Dindinnie Reservoir

Project Details:

AG Wilson was appointed by Scottish Water to deliver essential repairs to the Lower Scour Valve, draw-off valves, and balance valve at the Dindinnie Upper and Lower Reservoirs. This project was critical to improving operational reliability and safeguarding water quality for the Auchneel Water Treatment Works.

Delivering a Complex Scope

The works involved a comprehensive programme of enabling activities and asset restoration. Baseline and daily water sampling ensured water quality throughout the project. The team repaired the Lower Scour Valve to full operational order, installed a new manual isolation valve on the lower reservoir outlet pipe, and refurbished three draw-off valves in the upper reservoir. Additional tasks included de-silting the link and balance pipes between the towers and removing peat hags from the upper reservoir to improve flow and resilience.

Overcoming Technical Challenges

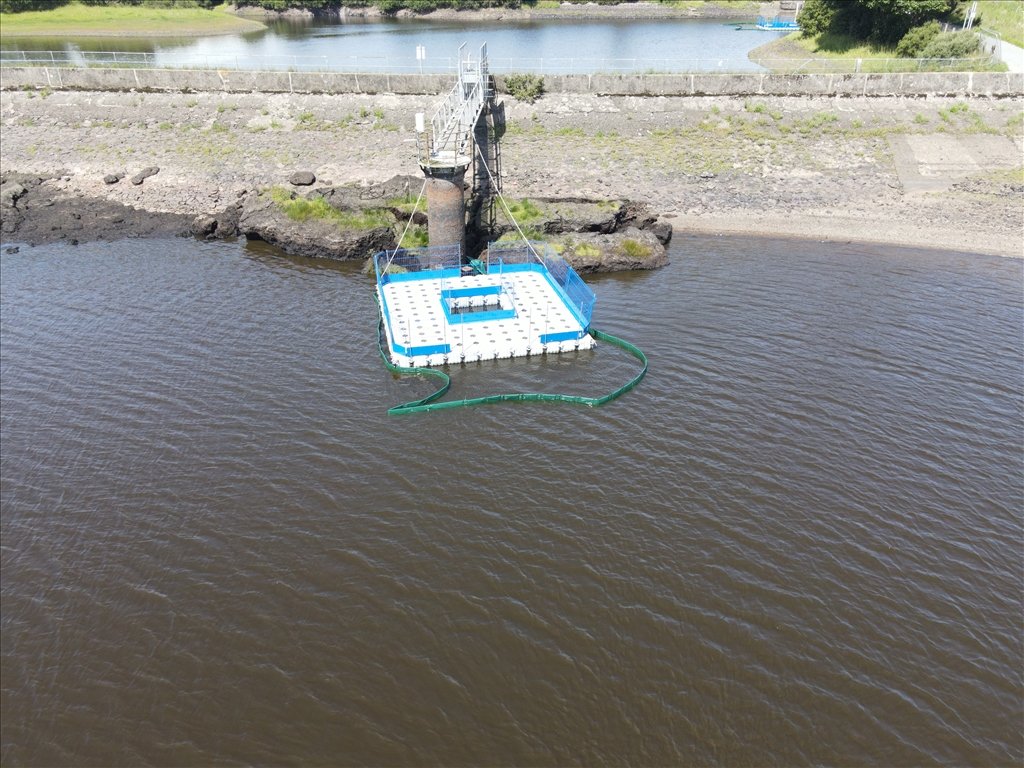

One of the most significant challenges was maintaining water supply during a period of drought, as the lower reservoir feeds directly into Auchneel Water Treatment Works. AG Wilson collaborated with Selwood Pumps to design and install an innovative over-pumping solution. A high-capacity electric centrifugal pump was deployed with eight-inch suction and discharge pipework, partially installed on floating pontoons that were extended as works progressed. This system ensured continuous water transfer and saved 1.5 litres of fuel per hour compared to the original diesel setup, reducing emissions and operating costs. Installation was rapid, with mechanical completion in one day and electrical commissioning within two days, minimising disruption to water supply.

Safety and Compliance

Operating in a remote location required rigorous safety planning. Joint Health and Safety audits with HSE and Scottish Water ensured compliance with Diving at Work Regulations 1997. Site security was maintained on a 24-hour basis, and vehicle speeds were restricted to 5mph to protect the public. A watch brief was also implemented to manage access, as the reservoir is a popular fishing spot.

Environmental Responsibility

Environmental protection was a priority throughout. A Pollution Prevention Plan was commissioned and implemented with zero negative impacts recorded. The Environmental Clerk of Works was present for compliance monitoring, and bunded generator pads were created away from the reservoir to reduce spill risk. Pumps used food-grade oils and were placed on drip trays for added protection, ensuring the highest standards of environmental care.

Outcome and Impact

The Dindinnie Reservoir project successfully restored critical assets to full operational service, improving water quality and reliability for thousands of customers. It demonstrated AG Wilson’s ability to deliver complex reservoir works through technical innovation, collaborative problem-solving, and uncompromising standards of safety and sustainability.